CLADDING

AliClad, Alucobond Plus, Alucolux, Alucobond A2, Equitone, Terreal, Cupaclad, Frontek, Cedral

SYSTEMS

Passive Fire Protection, Open Joint, T50, DAB, NV3 Nvelope, Building Accessories

Interiors

AliScreen, InnoCeil, InnoScreen, Innowood Internal Linings, Equitone, Dibond, Frontek

Roofing

Oakridge Pro 30, Duration Premium, Cedar Shingles, Cedar Shakes, ReadySlate

The Building Agency

About Us

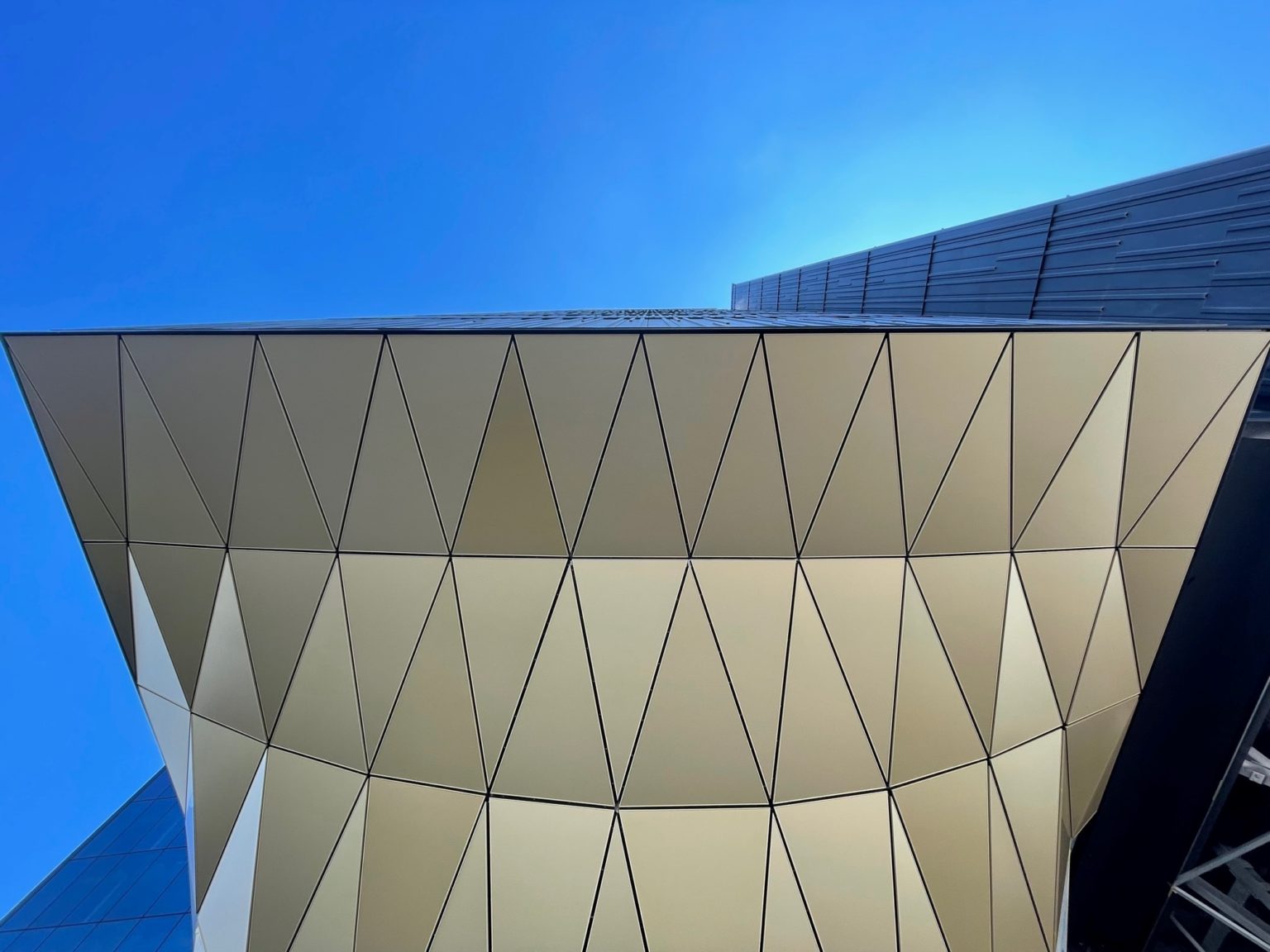

As building ‘skin’ specialists, we curate and source the best international facade products, so architects and contractors can design and build beautiful, enduring buildings that will be enjoyed for generations.

At The Building Agency we appreciate design and aesthetics, as much as we do technical performance. We understand quality is more than just a technical consideration and that there is beauty in both form and function. We want to source architects inspirational design materials that allow them to create with materials, forms, textures and patterns.

The Building Agency services different tiers of the market and different systems and installations can be tailored for different price points. Our collection includes globally renowned products used on some of the most innovative and architecturally applauded buildings in the world.